If your plan is to integrate a hot tub into your outdoor landscape, your setup procedure wills smooth, letting you relax under the stars with delay. By soaking in a superbly hot tub, respite can be provided from an exasperating moment. The tub water and jets help reducing strain, soothe too-tight muscles and preparing your system.

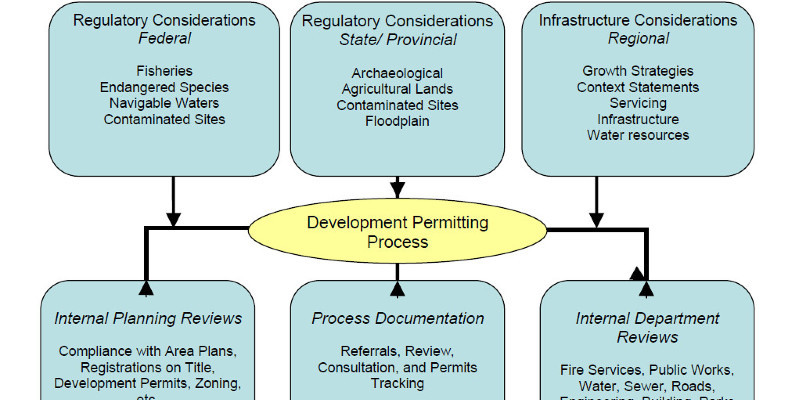

Codes and Regulations

Ensure that your hot tub installation conforms to all local building, electrical and plumbing codes. You may also need a building permit before you may begin your bathtub’s installation. Such as California and Minnesota, you need to set the tub back at least 5 feet. Into the edge of the structure of the tub, measure for an above-ground hot tub. As you would a swimming pool if your hot tub will have its high flush with the ground, measure the tub. Many building authorities require fences or other security barriers around hot tubs. Fence requirements are similar to those of swimming enclosures. Some local codes may allow tub covers that are approved to serve as security barriers.

Stable Surface

Put your hot tub on a surface that is stable, rather than. Concrete is quite expensive and takes some time to heal while installing a concrete slab is an ideal solution. If you go that path, use a 4-inch-thick reinforced concrete foundation that can support 120 lbs per square foot. Stone or crushed gravel will get the job done if concrete is not possible. Make sure the ground underneath has been compacted and can drain tub water and rainwater. Space around the spa’s perimeter for a walkway.

Electrical Supply

For security reasons, and to ensure your hot tub works properly with the electrical system of your home, employ a professional electrician to execute all applicable function. The plumber will set up a 50-amp neutrally protected Ground Fault Circuit Interrupter. The GFCI must be adjacent to the hot tub on an exterior wall at least 5 feet from any hot tub water or other water. To help have an notion of placement, measure the distance from the hot tub location to your main breaker box. Also, note if a house has a dedicated 50-amp breaker in the breaker boxif notyour electrician must add you to deal with the hot tub load.

Water Supply

You don’t need a water resource that is dedicated or special plumbing fixtures to fill your outdoor hot tub. Plenty of patience, and A long garden hose, a water source that is reliable are the tools you need. While you may face statewide, regional or local water restrictions that restrict your ability to fill your hot tub, Spa Association and the California Pool has some news. In March 2014, CPSA dispersed materials telling tub owners of their household water use compared to houses with grass-based landscaping. CPSA provided suggestions to spur water conservation efforts to increase.